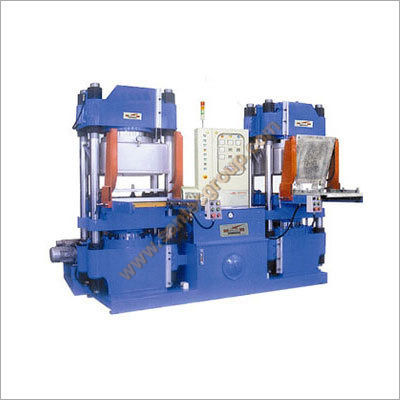

Compression Moulding Press 200 Tons Capacity

5000000 INR/Unit

தயாரிப்பு விவரங்கள்:

- பயன்பாடு Industrial

- கலர் Blue

- தயாரிப்பு வகை Compression Moulding Press

- பொருள் Stainless Steel

- உத்தரவாதத்தை 1 Years

- Click to view more

X

கம்ப்ரஷன் மோல்டிங் பிரஸ் 200 டன் திறன் விலை மற்றும் அளவு

- ௧

- அலகுகள்/அலகுகள்

- அலகுகள்/அலகுகள்

கம்ப்ரஷன் மோல்டிங் பிரஸ் 200 டன் திறன் தயாரிப்பு விவரக்குறிப்புகள்

- Blue

- Industrial

- Stainless Steel

- 1 Years

- Compression Moulding Press

கம்ப்ரஷன் மோல்டிங் பிரஸ் 200 டன் திறன் வர்த்தகத் தகவல்கள்

- கேஷ் இன் அட்வான்ஸ் (சிஐடி) காசோலை கேஷ் அட்வான்ஸ் (CA)

- ௧ மாதத்திற்கு

- ௨ மாதங்கள்

- மேற்கு ஐரோப்பா ஆஸ்திரேலியா வட அமெரிக்கா கிழக்கு ஐரோப்பா ஆப்ரிக்கா மத்திய கிழக்கு தென் அமெரிக்கா ஆசியா மத்திய அமெரிக்கா

- ஆல் இந்தியா

தயாரிப்பு விவரங்கள்

Application

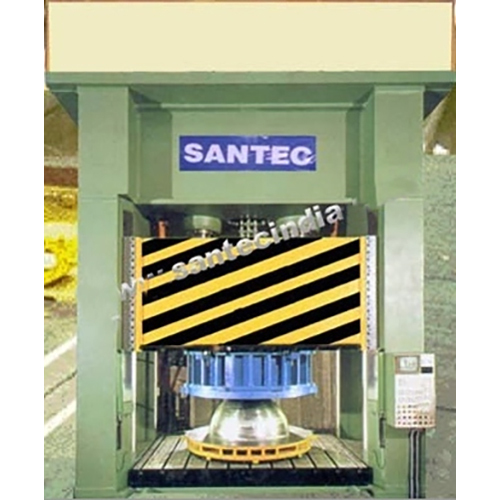

Santec's Laboratory Type Compression Molding Presses are widely used in following applications :

- Engineering or Technical colleges to give training to the students . i.e. I.I.T. , NIT , Engineering Colleges etc.

- Research & Development Laboratories i.e. Sri Ram Institute of Industrial Research , SPIC Science Foundation, Vikram Sarabhai Space Centre, Indira Gandhi Centre of Atomic Research

- Big Rubber Industries for R &D applications i.e. MRF, JK Tyres etc.

- Composites Molding applications, Plastic Processors etc.

- Laminates and Plastic cards manufacturing

Salient Features

- A specially designed heating system ensures a high uniformity of temperature of the plates. For this reason, the press is ideal for moulding rubber & plastic sheets or samples for laboratory tests.

- Digital PID controllers - FUJI (Japan) / WEST Make provided for accurate temp. measurements.

- Lab type compression molding presses can also be successfully used for moulding small series of rubber or plastic parts for mass production too. The structure is very rigid & can work in 3 shifts.

- Covered from all three side except front side for loading & unloading of mould inside the press. Safety photo guard are placed on the front side for operator's safety.

- 4-pillar type construction hence better alignment.

- PLC with colored touch type display unit for user friendly operation.

- Automatic press control device for programming an automatic production cycle by inserting upto 5 degassing cycles & curing time for moulding. At the end of the programmed time, the press automatically opens and a beeper signals the end of the cycle.

- Precision alignment and parallelism of the platens

- Flexible controls for sophisticated compression profiling

- Front side Table with Ball Transfer units

- Light / Lamp for the operator

Standard Accessories

- Electric Motor & Pump

- Photo Safety Guard (Sick Germany)

- Front Light for Operator's Convenience

- PLC with coloured touch type Display screen

- Pressure Setting through PLC with the help of Pressure Transmitter

- Emergency Push Button

- Two Hand Push Button Operation

- Tower Light

- PID type Temperature Controllers – Fuji / West make

- Mould Bank records in PLC

- LVDT (Potentiometer) controlled ram Movement

Optional

- Mold/ Platen Shuttles / sliding out arrangement

- Front side Tilting arrangement of the Top platen of the Press

- Thyristor to control the Multi temperatures during the curing time .

- Molded Part knockout arrangement

- Variable Displacement Pump.

- Data-Logger

- Mold plate ejectors

- Heating platens fitted with water recirculation circuit for the moulding of thermoplastic materials .

- Added safety enclosures

- Exhausts, enclosures for gas emissions

- Platen temperatures to 400 degree Celsius

- Mold thermocouple connections and temperature monitoring

- Multiple daylight designs

- Consolidated controls for multiple press systems

- Vacuum pump and reservoir

- Steam or oil platens

- Transfer molding cylinders and controls

- Core Pullers for middle part of the mold

| Description | LCMP-10 | LCMP-20 | LCMP-30 | LCMP-50 |

| Capacity (Tons) | 10 | 20 | 30 | 50 |

| Platen Size (mm) | 200x200 | 300x300 | 300x300 | 400x400 |

| Construction | 4-Pillars | 4-Pillars | 4-Pillars | 4-Pillars |

| Ram Movement | Up Stroke | Up Stroke | Up Stroke | Up Stroke |

| Daylight (mm) | 300 | 300 | 300 | 350 |

| Stroke (mm) | 300 | 300 | 300 | 350 |

| Temperature (Degree Celcius) | 400 | 400 | 400 | 400 |

| Electrical Motor (H.P.) | 3 | 5 | 5 | 5 |

| Pressure Adjustment | Pr. Trans Mitter | Pr. Trans Mitter | Pr. Trans Mitter | Pr. Trans Mitter |

| Heating Method | Electric/Oil | Electric/Oil | Electric/Oil | Electric/Oil |

| Power Supply (Volts) | 415/380 | 415/380 | 415/380 | 415/380 |

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

கைபேசி number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese