Precured Tread Rubber Molding Presses or PCTR PRESSES

Product Details:

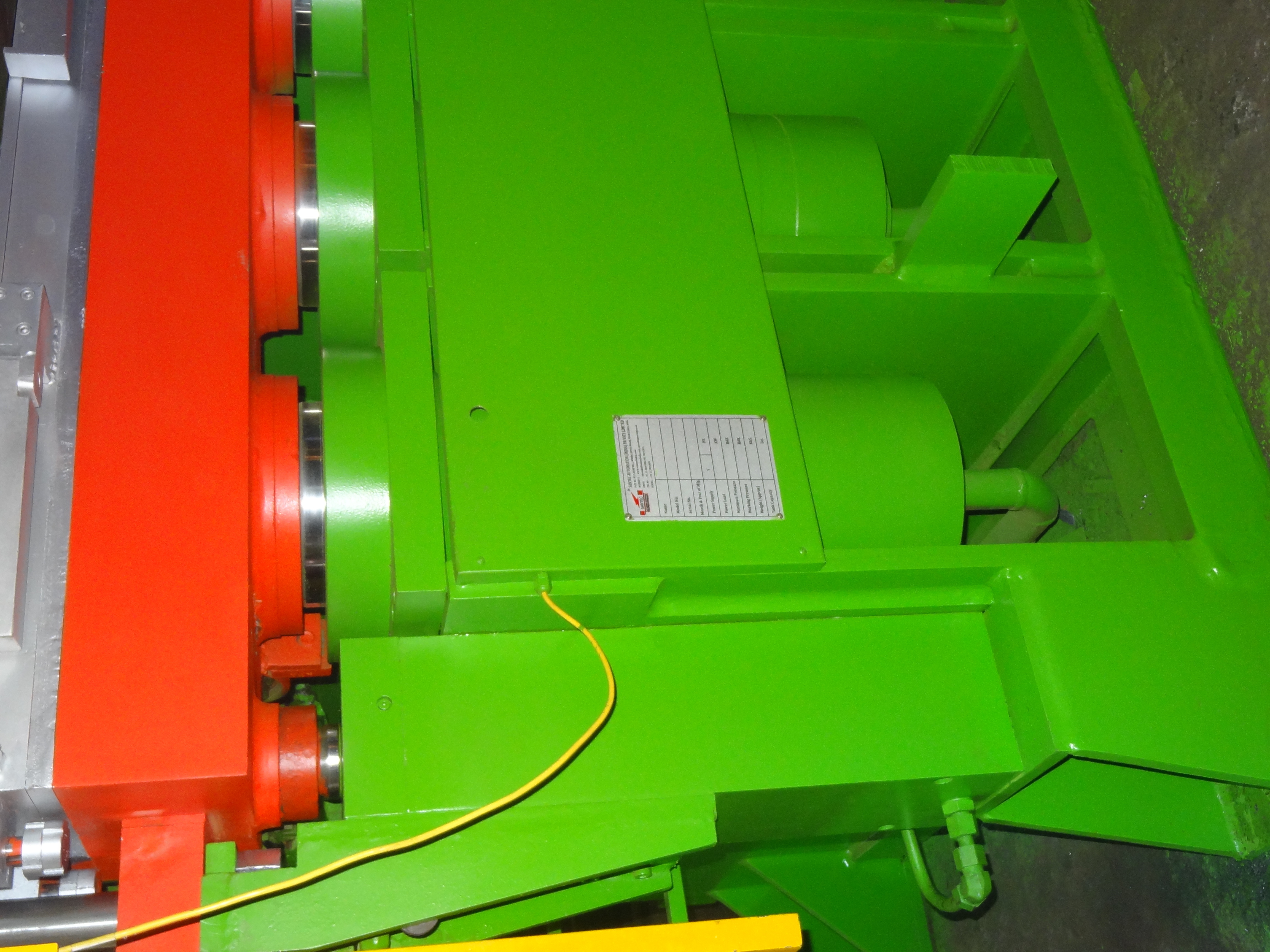

- Material Cast iron

- Computerized No

- Automatic Grade Automatic

- Control System PLC Control

- Cooling System Water Cooling

- Click to view more

Precured Tread Rubber Molding Presses or PCTR PRESSES Price And Quantity

- 1 Unit

- 600000 INR/Unit

Precured Tread Rubber Molding Presses or PCTR PRESSES Product Specifications

- Automatic

- PLC Control

- Water Cooling

- No

- Cast iron

Precured Tread Rubber Molding Presses or PCTR PRESSES Trade Information

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- 1 Unit Per Month

- 2 Months

- Australia, Western Europe, Middle East, Central America, Africa, South America, Asia, Eastern Europe, North America

- All India

Product Description

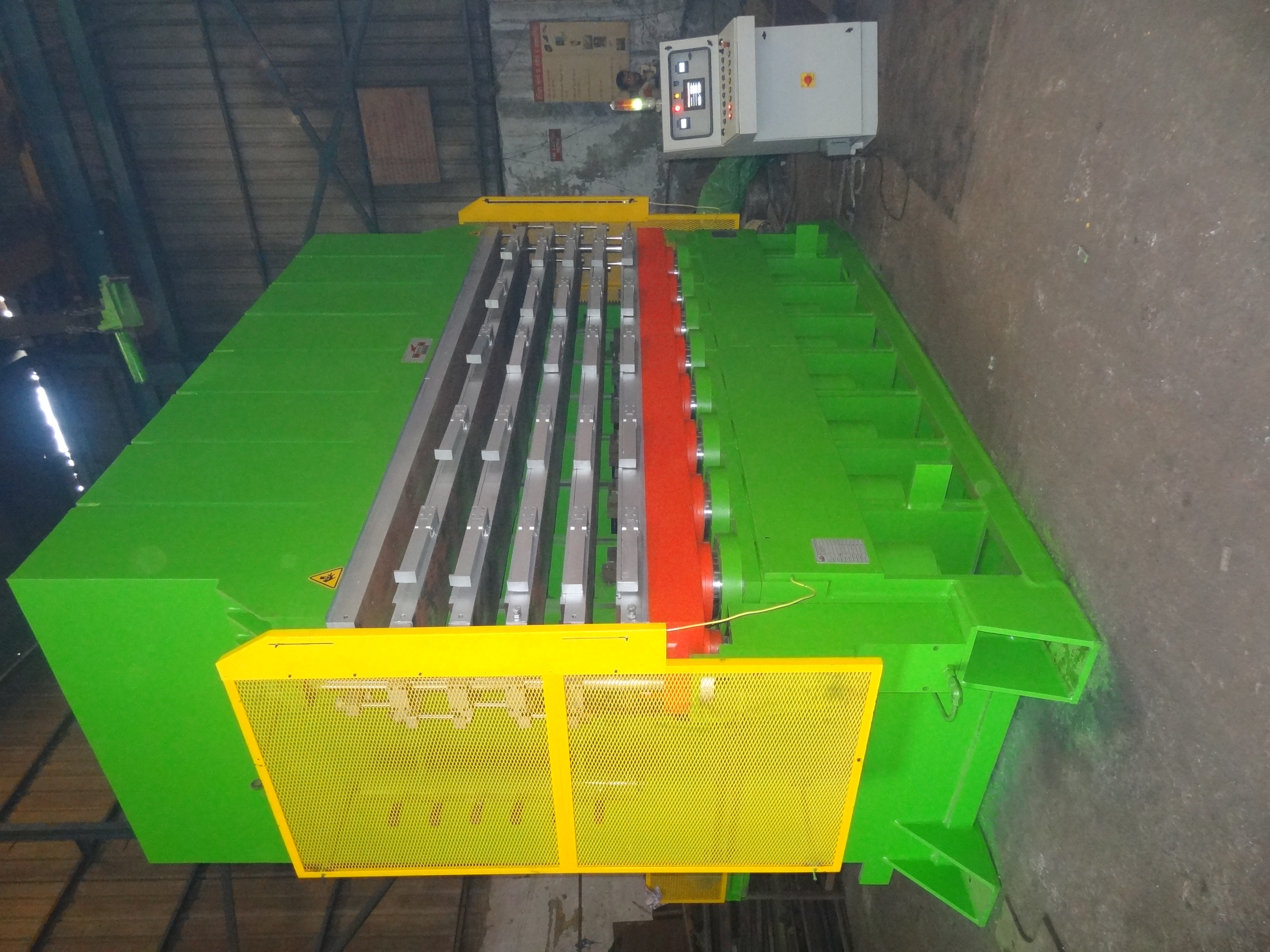

Precured Tread Rubber Molding Press

We are instrumental in manufacturing and exporting Precured Tread Rubber Molding Press. This press is one of the best ways, which is environmental friendly too, to recycle the used tires. Offered press is thus highly demanded around the globe, for production of the tire strips of car, aircraft, truck and light truck. This press is known for its amazing functioning that is highly efficient and requires no additional knowledge. We have made Precured Tread Rubber Molding Press available in market, at industry leading prices.

Technical Specifications Of Precured Tread Rubber Molding Presses:

Application

- Car

- Light Truck

- Truck

- Aircraft

Salient Features

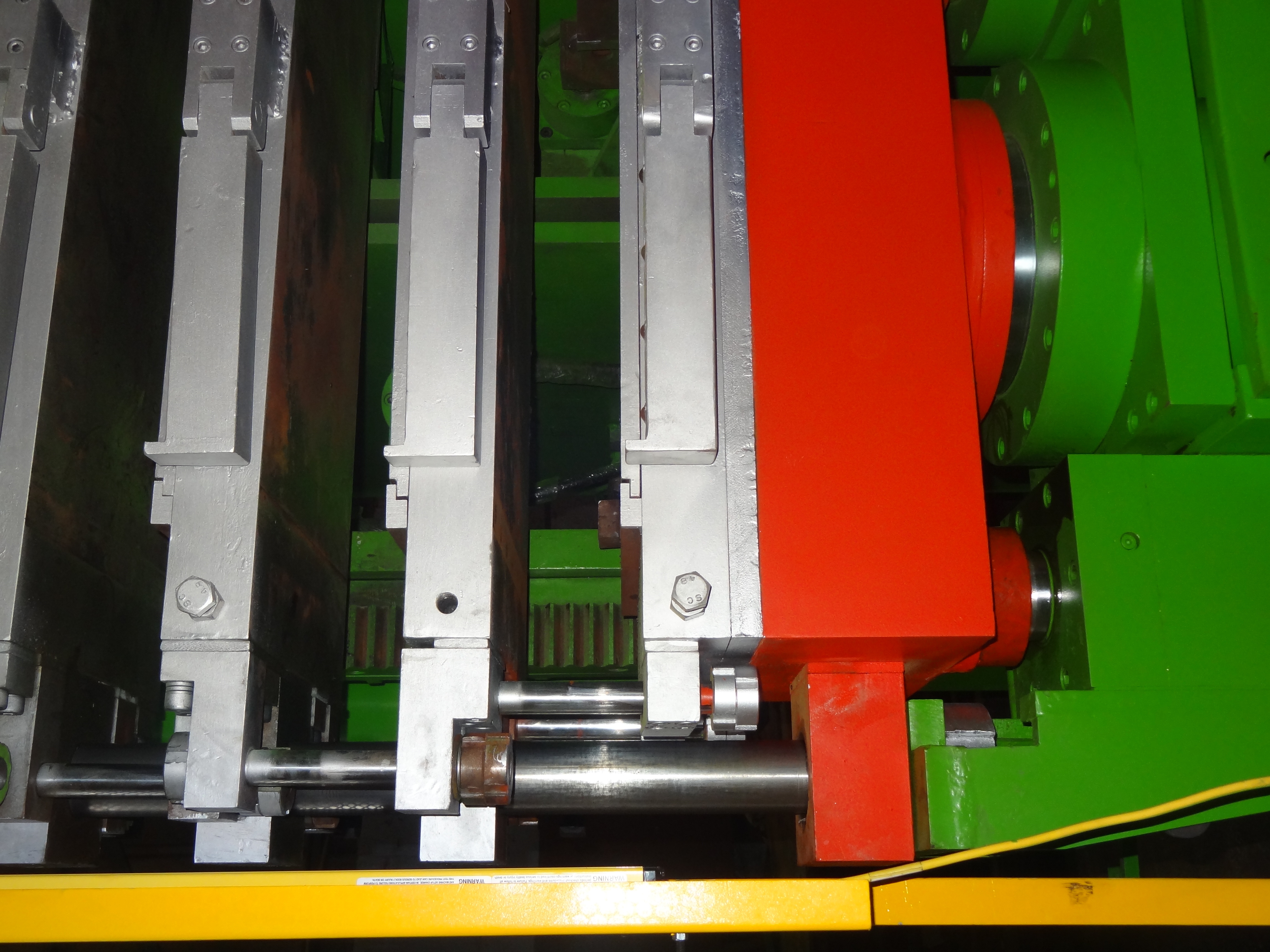

- The low noise hydraulic power pack unit is designed as per international standards & assembled with best quality of valves & other imported components. The press is specially designed as per ISI guidelines, hence standard seals in heavy duty cylinders, bronze- bushes with lubrication arrangement are used.

- The precisely honed carbon steel seamless tubes are assembled with hard chrome plated piston rod, EN-9 & international quality sealing elements, imported from Germany, U.K. & Japan. Manifold block mounted valves minimise piping, hence no leakage with easy replacement & maintenance.

- With the help of OMRON make user friendly PLC no. of breathings (even in milli-seconds), curing time, temp. variation range, desired pressure etc. The display screen ( MMI ) provides accurate reading for every measurement.

- During the process, if the electric motor stops and pressure falls below certain value, it automatically starts to maintain the pressure producing less strain on the hydraulic system. The innovative engineering saves electricity, produces less noise, pollution and significantly improves product quality

- Soft opening of moulds are provided just after the curing period for better retention of the shape of the moulded parts. A heavy gauge, ultrasonically tested plates are used to make the frame more rigid & sturdy enough to withstand the load during fast & frequent operations.

- Precise machining of the structural members are done after normalising to get the parallelism between platen & bed and right angularity, between bed and the moving platen.

|

MODELS |

STP - 360 |

STP - 650 |

STP - 800 |

STP - 2000 |

STP - 1000 |

|

Clamping Force (T) |

360 |

650 |

800 |

2000 |

1000 |

|

Table Size (mm) |

305 x 3650 |

305 x 8000 |

400 x 8000 |

400 x 11000 |

350 x 5500 |

|

Daylight (MM) |

125 each |

125 each |

125 each |

150 each |

125 each |

|

No. of Daylight / Layers |

4 Nos. |

5 Nos. |

5 Nos. |

5 Nos. |

4 Nos. |

|

Stroke of Main Cylinder |

500 mm |

600 mm |

550 mm |

750 mm |

500 mm |

|

No. of Cylinders |

6 Nos. |

12 Nos. |

8 Nos. |

20 Nos. |

10 Nos. |

|

Piston dia of each cylinders |

200 mm |

200 mm |

250 mm |

250 mm |

250 mm |

|

Electric Motor (H.P.) |

10 H.P. |

20 H.P. |

25 H.P. |

30 H.P. |

25 H.P. |

|

Working Pressure (Bar) |

200 Bar |

200 Bar |

200 Bar |

200 Bar |

200 Bar |

|

Weight (approx) |

35 Tons |

75- 80 Tons |

80 - 85 Tons |

130 tons |

50 tons |

|

Specific Pressure |

40 to 45 Kg/cm2 |

40 to 45 Kg/cm2 |

40 to 45 Kg/cm2 |

45 to 50 Kg/cm2 |

45 to 50 Kg/cm2 |

|

Heating Method |

Steam / Thermic Oil |

Steam / Thermic Oil |

Steam / Thermic Oil |

Steam / Thermic Oil |

Steam / Thermic Oil |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese