Welcome to Our Company -

SMC / DMC / FRP Moulding Presses

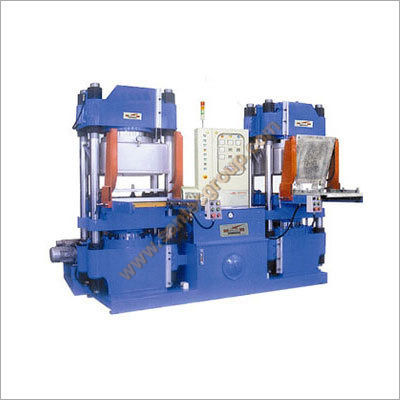

Product Details:

- Usage Industrial

- Material Stainless Steel

- Product Type Moulding Presses

- Color Blue

- Warranty 1 Years

- Click to view more

X

SMC / DMC / FRP Moulding Presses Price And Quantity

- 1 Unit

SMC / DMC / FRP Moulding Presses Product Specifications

- Moulding Presses

- 1 Years

- Blue

- Industrial

- Stainless Steel

SMC / DMC / FRP Moulding Presses Trade Information

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- 1 Unit Per Month

- 2 Months

- South America, Western Europe, Middle East, Central America, Africa, Australia, Asia, Eastern Europe, North America

- All India

- ISO 9001-2015

Product Description

Downstroking SMC/DMC/FRP Compression Moulding are designed to provide greatest degree of precision. These machine provide acute control over the process with desired flexibility. Different applications of the machine include the following.

-

SMC/DMC/FRP Moulded parts

-

Bekallite moulding

-

Composite material/others polymers mouldings

-

clutch facing/rubber parts moulding

Versatile Moulding Solutions

Our hydraulic moulding presses cater to a variety of industrial needs, including SMC, DMC, FRP, and rubber moulding. Designed for flexibility and reliability, these machines empower manufacturers to undertake complex composite and bulletproof moulding projects with confidence.

Superior Build and Automation

Crafted from stainless steel and finished with painted surfaces, these automatic presses provide longevity and high performance. Their advanced hydraulic power source ensures smooth operation across demanding applications, optimizing efficiency for consistent production results.

Wide Range of Capacities

From 2 tons to 300 tons of weight capacity and pressure ranges of 5 to 4000 tons bar, our presses are built to handle large-scale industrial requirements. Whether you require them for small or massive production, our machines offer the adaptability your operation needs.

FAQs of SMC / DMC / FRP Moulding Presses:

Q: How do SMC/DMC/FRP Moulding Presses operate in industrial applications?

A: SMC/DMC/FRP Moulding Presses use hydraulic power to shape and mould various materials automatically, providing efficient and repeatable results across applications such as composite, rubber, and bulletproof manufacturing.Q: What materials are compatible with these moulding presses?

A: These presses are designed to work with materials including Sheet Moulding Compound (SMC), Dough Moulding Compound (DMC), Fiber Reinforced Polymer (FRP), and rubber, catering to both traditional and advanced industrial needs.Q: When is it ideal to use these presses for production?

A: These presses are suited for use when high precision, large tonnage, and reliable automation are required, especially in continuous or high-volume production environments.Q: Where can these moulding presses be supplied or exported from?

A: We manufacture and supply these hydraulic presses from India, serving both domestic and international clients as reliable exporters and suppliers.Q: What is the process for moulding using these machines?

A: The process involves placing the raw material into the mould, setting the desired pressure and temperature, and allowing the automatic hydraulic system to shape and cure the product according to set specifications.Q: What are the benefits of using an automatic hydraulic moulding press?

A: Automatic hydraulic moulding presses offer consistent quality, reduced manual intervention, enhanced safety, and the ability to handle complex moulding tasks efficiently, resulting in higher productivity and lower operational costs.Q: How long is the warranty period for these presses?

A: Each press comes with a warranty ranging from 12 months to 1 year, ensuring peace of mind and support for maintenance and repairs during the initial period of use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese