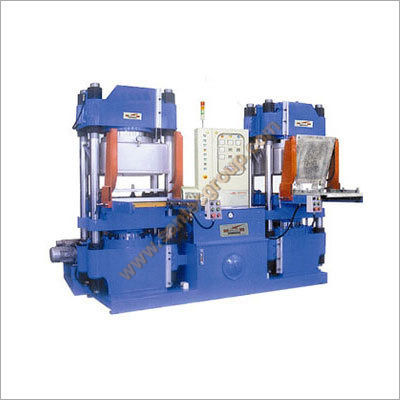

Upstroking Type Compression Moulding Presses

Product Details:

- Color Blue

- Product Type Compression Moulding Presses

- Usage Industrial

- Material Stainless Steel

- Warranty 1 Years

- Click to view more

Upstroking Type Compression Moulding Presses Price And Quantity

- 1 Unit

- INR

Upstroking Type Compression Moulding Presses Product Specifications

- Blue

- 1 Years

- Compression Moulding Presses

- Industrial

- Stainless Steel

Upstroking Type Compression Moulding Presses Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 1 Unit Per Month

- 2 Months

- Australia, North America, South America, Eastern Europe, Central America, Western Europe, Middle East, Africa, Asia

- All India

Product Description

Upstroking Type Compression Molding Presses

Application Areas:

- Melamine Crocking Moulding

- Composite materials mouldings i.e. Bullet proof Jackets, Helmets, etc.

- Plastic sheets etc.

- Ply boad, MDF sheets, Particle Boards

- Conveyor Belts / V-Belts, Rubber mats / Flaps/ Tyres / tubes etc.

Upstroking Type Compression Moulding Presses from Santec are designed as per international standards. These presses can also be tailor made as per client's specific application requirements. They can be used for different application across diverse industries such as :

- Rubber products for automobiles, medical equipments etc.

- Melamine Crocking Moulding

- Composite materials mouldings i.e. Bullet proof Jackets, Helmets, etc.

- Laboratory applications

- Plastic sheets etc.

- Ply board, MDF sheets, Particle Boards

- Conveyor Belts / V-Belts, Rubber mats / Flaps/ Tyres / tubes etc.

Salient Features :

Salient Features of Upstroking Type Compression Moulding Presses

- The low noise hydraulic power pack unit is designed as per international practices & assembled with internationally accepted make valves & other components. The presses are designed as per 151 guidelines, hence standard seals in heavy duty cylinders, bronze- bushes with lubrication arrangement are used.

- The precisely honed carbon steel seamless tubes are assembled with hard chrome plated piston rod, EN-9, international quality sealing elements, imported from koria & Japan.

- Manifold block mounted valves minimising piping, hence no leakage & easy replacement & maintenance.

- With the help of PLC no. of breathings, breathing duration even in mili-seconds, curing time, temp. of platens, temp. variation range, desired pressure etc. may be programmed in the PLC.

- During curing period, the electric motor stop & if pressure drops below certain value, it automatically starts maintain the pressure hence less strain to the hydraulic system, saves electricity, less noise, pollution, improves product quality

- Soft opening of moulds is provided just after the curing period for the safety of the moulded parts

- Ultrasonically tested quality plates are used of heavy thickness to make the frame more rigid & capable enough to the load during frequent & fast operations

- All platens are having parallel accuracy, as platens are precisely grinded upto 0.01 to 0.02 mm parallel accuracy, with T-slots/ tapped holes & provision of heating & cooling arrangement as per DIN standards.

Technical Specifications :

Technical Specifications of Upstroking Type Compression Moulding Presses

|

Model |

SCM-15 |

SCM-30 |

SCM-50 |

SCM-75 |

SCM-100 |

SCM-150 |

SCM-200 |

SCM-250 |

SCM-300 |

SCM-400 |

SCM-500 |

SCM-1000 |

|

|

Pressing capacity (Tons) |

15 |

30/25 |

50/60 |

75 |

100 |

150 |

200 |

250 |

300 |

400 |

500 |

1000 |

|

|

Heating Platen size (mm) |

250x250 |

300x300 |

350x350 |

400x400 |

450x450 |

500x500 |

600x600 |

700x700 |

800x800 |

900x900 |

1000x1000 |

1500x1500 |

|

|

Day light (mm) |

8" |

10" |

12" |

14" |

16" |

18" |

20" |

24" |

24" |

30" |

36" |

40" |

|

|

No. of daylight |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

|

|

Stroke length (mm) |

8" |

10" |

12" |

14" |

16" |

18" |

20" |

24" |

24" |

24" |

30" |

30" |

|

|

Platen temperature (max. Degree cel) |

250 |

250 |

250 |

250 |

250 |

250 |

250 |

250 |

250 |

250 |

250 |

250 |

|

|

Heating capacity (Km/platen) |

3 |

4.5 |

4.5 |

6 |

6 |

6 |

9 |

9 |

12 |

12 |

12 |

15 |

|

|

Oil tank capacity (Ltr.) |

100 |

150 |

200 |

250 |

350 |

400 |

400 |

500 |

600 |

600 |

800 |

1200 |

|

|

Insulation plate thickness (mm) |

20 |

20 |

25 |

25 |

25 |

30 |

30 |

30 |

30 |

30 |

30 |

30 |

|

|

No. of cylinders |

1 |

1+2 |

1+2 |

1+2 |

1+2 |

1+2 |

1+2 |

1+2 |

1+2 |

1+2 |

1+2 |

1+4 |

|

|

Type cylinders |

Double Acting Cylinders |

Single Acting + 2ns. Jacking Cylinders |

Single Acting + 2ns. Jacking Cylinders |

Single Acting + 2ns. Jacking Cylinders |

Single Acting + 2ns. Jacking Cylinders |

Single Acting + 2ns. Jacking Cylinders |

Single Acting + 2ns. Jacking Cylinders |

Single Acting + 2ns. Jacking Cylinders |

Single Acting + 2ns. Jacking Cylinders |

Single Acting + 2ns. Jacking Cylinders |

Single Acting + 2ns. Jacking Cylinders |

Single Acting + 4ns. Jacking Cylinders |

|

|

Bore of piston size of main cylinders (each) |

5" |

6" |

8" |

9" |

10" |

12" |

14" |

16" |

18" |

20" |

22" |

30" |

|

|

Max. working pressure (Kg/cm2) |

210 (Kg/cm2) |

210 (Kg/cm2) |

210 (Kg/cm2) |

210 (Kg/cm2) |

210 (Kg/cm2) |

210 (Kg/cm2) |

210 (Kg/cm2) |

210 (Kg/cm2) |

210 (Kg/cm2) |

210 (Kg/cm2) |

210 (Kg/cm2) |

210 (Kg/cm2) |

|

|

Mode of heating |

Electric |

Electric |

Electric |

Electric |

Electric |

Electric |

Electric |

Electric |

Electric |

Electric |

Electric |

Electric |

|

|

Electric motor 3 phase, 1440 r.p.m. |

3H.P. |

5H.P. |

5H.P. |

5H.P. |

7.5 H.P. |

7.5 H.P. |

10 H.P. |

15 H.P. |

20 H.P. |

25 H.P. |

30 H.P. |

50 H.P. |

|

|

Pump |

Vane Pump |

Vane Pump |

Vane Pump |

Vane Pump |

Vane Pump |

Vane Pump |

Vane Pump |

Vane Pump |

Vane Pump |

Vane Pump |

Vane Pump |

Vane Pump |

|

|

Weight of the Press (Tons) |

2.5 |

3-4 |

5 |

5 |

6 |

8 |

10 |

12 - 13 |

15 |

16 |

18-20 |

30-35 |

|

|

Speeds |

Approach |

20 |

50 |

50/60 |

70-100 |

80-100 |

90-100 |

100 |

100 |

100 |

100 |

100 |

150 |

|

Pressing |

3 |

8 |

10 |

15-20 |

15 -20 |

15 -20 |

15 -20 |

15 -20 |

15 -20 |

15 -20 |

15 -20 |

15 -20 |

|

|

Return |

30 |

60 |

60/70 |

120 |

120 |

120 |

120 |

120 |

120 |

120 |

120 |

120 |

|

|

T-slots size |

T-16 |

T- 16 |

T- 16 |

T-20 |

T-20 |

T-20 |

T-20 |

T-20 |

T-20 |

T-20 |

T-20 |

T- 20 |

|

|

Noise - dba |

85 |

85 |

85 |

85 |

85 |

85 |

85 |

85 |

85 |

85 |

85 |

85 |

|

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese